Discover the brands and technologies from our business units Henkel Adhesive Technologies and Henkel Consumer Brands.

Zooming in on the palm oil supply chain to get proof of zero deforestation

Ingredients that build foam are important for laundry detergent, shampoo and shower gel. However, raw materials like palm kernel oil that form the basis for making these ingredients often travel a long way before they become part of a finished product – and the journey can be very complex. That makes it difficult for companies to know exactly how the raw materials were made or which specific region they were produced in. At Henkel, we’re joining forces with pioneering partners to explore digital technologies with the potential to increase traceability and transparency in the palm oil industry, and to support our commitment to sustainable sourcing.

Zero deforestation for palm oil

Palm oil and palm kernel oil have grabbed a lot of headlines in recent years. These two raw materials are extracted from the fruit of the oil palm tree, and the expansion of plantations for this crop has been linked to deforestation. At Henkel, we use surfactants that are derived from palm kernel oil to make detergent and cosmetic products, and we are absolutely committed to making sure that none of the ingredients we use are connected to deforestation. But the global supply chain for palm-related materials is extremely complex.

The fruit is grown on a plantation, then processed in mills and refineries. Palm kernel oil only accounts for about 10 percent of the plantation yield, with oil taken from the flesh of the fruit providing the other 90 percent. For this reason, palm kernels from different plantations are mixed in mills, and are then shipped and reprocessed multiple times before a surfactant arrives at our factory. Although this long and tangled journey is difficult to follow, we know transparency and traceability are the keys to ensuring sustainable agricultural practices and fair labor conditions in this industry.

By 2025, we want to achieve full traceability, which will only be possible if we collaborate, invest and openly embrace a wide range of innovative solutions.

Christine Schneider, Senior Manager Global Sustainability in the Laundry & Home Care business unit at Henkel

Together for transparency in the palm oil supply chain

That’s why Henkel is a founding member of the cross-industry initiative Action for Sustainable Derivatives, for example, which brings together more than 25 companies with the shared goal of generating more transparency in the palm value chain. On top of this, we work closely with our suppliers to map our direct and indirect supply chain. This involves new levels of openness and trust when sharing information based on compliance.

“There is a high common interest in the traceability of our palm kernel-based ingredients, as this is the only way we can take responsibility along the supply chain and ensure ecological balance,” says Christine Schneider, Senior Manager Global Sustainability in the Laundry & Home Care business unit. “Right now, Henkel can trace 84 percent of its materials back to the mill. By 2025, we want to achieve full traceability. We know that will only be possible if we collaborate, invest and openly embrace a wide range of innovative solutions.”

Mobile mapping for true traceability

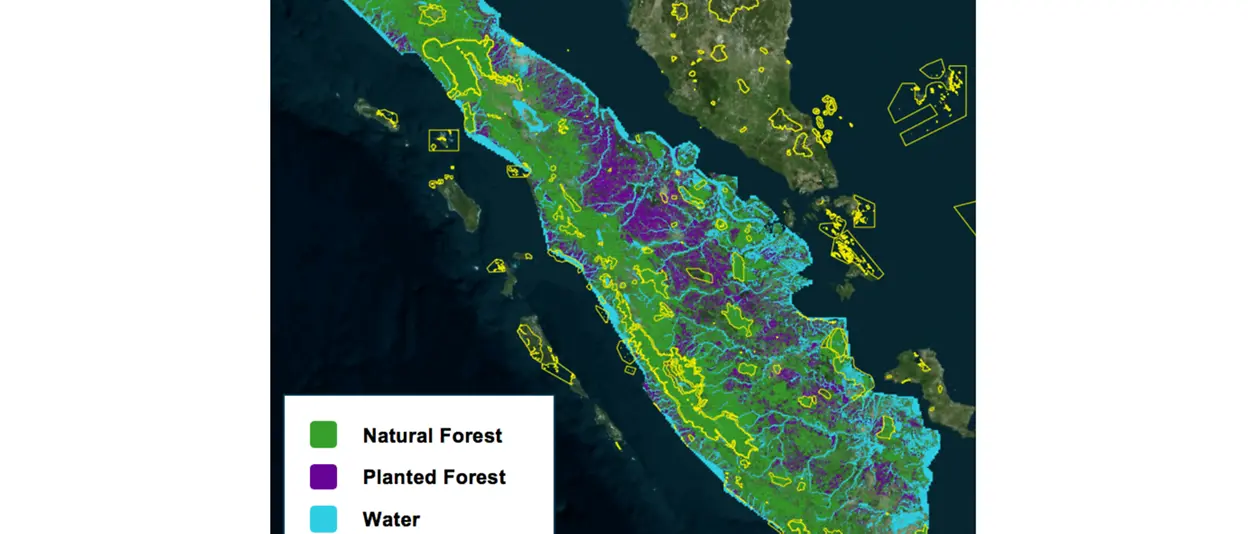

One example of this approach is our pilot project with the US-based tech company Orbital Insight. Its technology anonymously collects GPS data from cell phones, then uses it to work out which oil palm plantations are most likely to be supplying a mill by identifying patterns in how trucks travel around the local area. The analysis can also be matched with maps from Global Forest Watch to identify restricted or protected areas and prove that no GPS data from cell phones was detected within a certain timeframe. This technology is especially valuable during a global pandemic because it doesn’t require face-to-face interactions like on-site audits.

It’s particularly hard to trace goods during the first part of the value chain – our solution gives companies like Henkel a powerful tool to do so.

Bryan Yates, General Manager Europe and Middle East Africa at Orbital Insight

Satellite imaging is already used to monitor changes in land use – and to spot plantations that expand through deforestation. By combining the GPS and satellite data, Henkel was able to see if the mills in its value chain were being supplied by these plantations. The pilot project covered 15 mills in Indonesia for around one year and did not find any evidence of a connection to unsustainable farms.

“It’s particularly hard to trace goods during the first part of the value chain, when the fruit moves from a plantation to a mill,” says Bryan Yates, General Manager Europe and Middle East Africa at Orbital Insight. “Our solution offers detailed data in real-time – giving companies like Henkel a powerful tool to boost their sustainable sourcing approach.”

Pioneering with palm oil

This pilot project is just one element of Henkel’s commitment to sustainability in the palm oil industry. We’ve set far-reaching goals for 2025 that build on the progress achieved until 2020. This includes covering 100 percent of our demand with certified oils, achieving full traceability, and continuing our efforts to improve livelihoods for smallholders and protect nature.

Our future plans for palm oil and palm kernel oil create potential for an even wider positive impact – which keeps us moving forward in our commitment to responsible sourcing for all of the ingredients we use.

Christine Schneider, Senior Manager Global Sustainability in the Laundry & Home Care business unit at Henkel

“We’re always open to innovative ways of supporting transformation in the palm industry,” says Christine Schneider. “Our future plans for palm create potential for an even wider positive impact because ideas from this industry are often transferred to increase sustainability for other raw materials – which keeps us moving forward in our commitment to responsible sourcing for all of the ingredients we use.”